Plastic Pallets vs Wood Pallets: Which Variant Is the Best for Your Business?

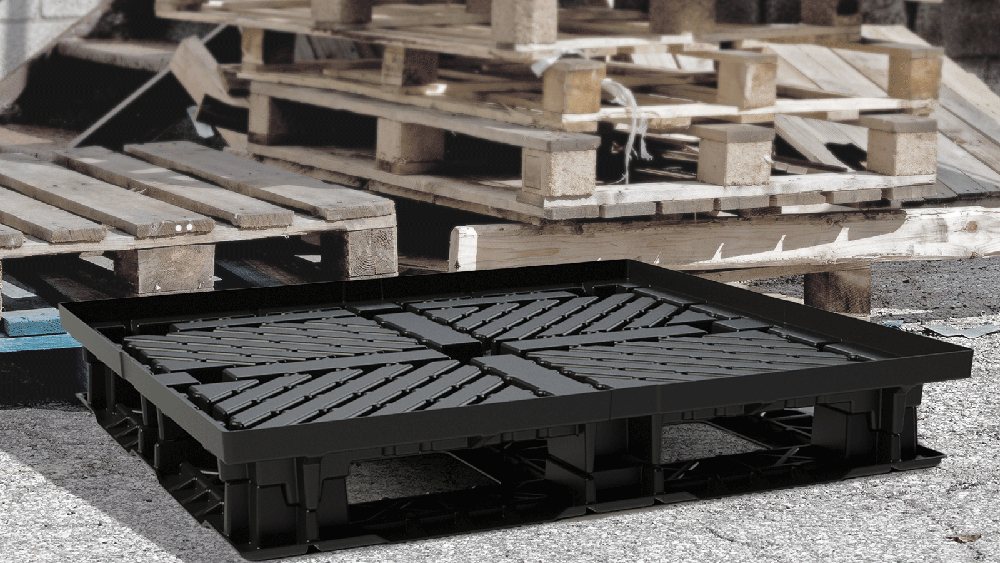

Can you imagine 4 billion pallets? This is exactly the amount that was produced in Europe in 2022, 90% of them were made of wood and 10% of plastic.

Both types can be helpful in various important ways, including processes such as protection and safety, standardization, compatibility, and other aspects in the field.

Let’s examine the differences between these types and explore how to choose the most suitable one for your business needs.

Why Do We Need Pallets?

When you buy pallets, it is important that you know for what purpose you need them and therefore choose them according to their special characteristics. It is easier if you know the difference. We will go through the details about each type.

Pallets serve as sturdy platforms for the storage and movement of goods, ensuring effective handling and easy stacking. Even used pallets will provide you with some essential advantages for the field of transportation, such as increased safety.

Wood Pallet Benefits

- Cost-effective: Wooden pallets are an affordable option for companies because of their availability and low manufacturing costs. Compared to their analogs, they are significantly more cost-effective, with a price up to six times lower.

2. Sustainability: They have an average lifespan of 5 to 7 years.

2. Sustainability: They have an average lifespan of 5 to 7 years.

3. Extremely durable and sturdy: They are known for their strength and resilience, allowing them to withstand heavy loads and rough handling during transportation and storage.

4. Easy repair and maintenance: In case of damage, they can be easily repaired or replaced, reducing the frequency of replacements and minimizing costs.

5. Recycling: A high percentage of structures made of timber are recycled or rebuilt. This contributes to sustainability and recycling in particular. By rebuilding them, you can contribute to the eco-friendliness as well.

6. The common belief that the use of wooden pallets contributes to deforestation is not correct. Trees are rarely cut specifically for their production, as they are made from recycled lumber and wood residues. Instead, the main purpose of cutting down trees is to obtain valuable materials for the production of building materials and furniture.

Plastic Pallet Benefits

Durability and longevity: Plastic pallets are remarkably sturdy and resistant to damage, as they can be used repeatedly. They consistently deliver reliable performance, resulting in optimized operations, reduced expenses, and higher long-term profits.

Durability and longevity: Plastic pallets are remarkably sturdy and resistant to damage, as they can be used repeatedly. They consistently deliver reliable performance, resulting in optimized operations, reduced expenses, and higher long-term profits.- Hygienic and easy to clean: They are non-porous and can be easily cleaned and sanitized, reducing the risk of contamination.

- Consistent dimensions and weight: They are manufactured with standardized dimensions, providing uniformity that simplifies handling and storage in warehouses, logistics operations, and other processes.

Wood Pallet Disadvantages

1. Susceptibility to damage: They are prone to damage from forklifts and rough handling, which can result in broken boards, splinters, or loose nails. This can lead to higher maintenance and repair costs.

2. Potential for contamination: There is a potential for contamination as they can harbor bacteria, mold, or pests if not properly cleaned or treated.

Plastic Pallet Disadvantages

- Higher upfront cost: They tend to have a higher initial cost compared to wooden equivalents. This can be a significant factor for organizations with tight budgets or those that require a large number of them.

- Limited load capacity: These variants generally have lower load capacities compared to their wooden counterparts. This can be a disadvantage for companies dealing with exceptionally heavy or dense products.

- Less widespread acceptance: While plastic options are widely used, there are still certain industries or supply chains that prefer or require wooden options due to established systems, equipment compatibility, or specific regulations.

- The production process: The production of a standard 48×40″ structure consumes eight times more raw material and five times more energy, emits more emissions, and generates more waste compared to a comparable reusable wood pallet.

Which Type Is Used in Which Business?

The choice of pallets euro pallets varies based on factors such as individual requirements, industry standards, and product characteristics. For instance, wood options are commonly used in manufacturing, warehousing, retail, and construction. Pallet delivery is something that no business can do without.

Different Types of Pallets in E-commerce, Logistics, and Warehousing

Pallets are used in e-commerce, logistics, and warehousing to facilitate efficient handling, storage, and transportation of goods. In e-commerce, they enable streamlined order fulfillment and secure packaging.

In logistics, they serve as standardized units for organizing and moving goods, optimizing loading and unloading as well as storage in warehouses and distribution centers. They contribute to supply chain optimization by ensuring compatibility across different stages of the logistics process.

Which Ones Are Best for Long Journeys?

Plastic structures are often considered the best choice for long-distance transportation as they are durable, moisture-resistant, and resistant to chemicals. Plastic pallets are often the best choice for long-distance transportation because they are durable, moisture-resistant, and resistant to chemicals.

The unique properties of plastic make it an ideal material for constructing various transportation components, such as containers, packaging, and infrastructure.

TAGS: #3PL #4PL #5PL #Fulfillment #Pallets #Warehouse